Subsystems

- Photovoltaic (PV) solar modules on all six sides.

- Battery management (BM) and power supply monitoring and management (TU) modules.

PV modules

Each module carries six single junction 20mm x 40mm GaAs solar cells (19.5% efficiency, AM0).

The partner company Metallux S.A. conducted extensive tests to define and tune the cell encapsulation process, pad wire bonding, spacer and coverglass positioning and succeded in producing our perfectly working solar generators.

The substrate of the module is a home designed 0.8mm two layer PCB made of high Tg FR4. Some sensors are integrated on front and back of this PCB.

Prototype and production units underwent thorough thermal and vacuum tests, visual inspection with analytical dimensional monitoring and could be electrically characterized thanks to the partner company SunAge S.A. who provided technical support and easy access to cell test equipment.

Batteries

Two secondary batteries are used: a Lithium-Ion battery (2300mAh) and a Lithium-Polymer battery (1500mAh).

Both batteries are separately monitored for temperature, End Of Charge/End Of Discharge (EOC/EOD) voltage and discharge overcurrent through dedicated battery management channels.

In order to temperature cycle several battery makes, an automated test system was devised.

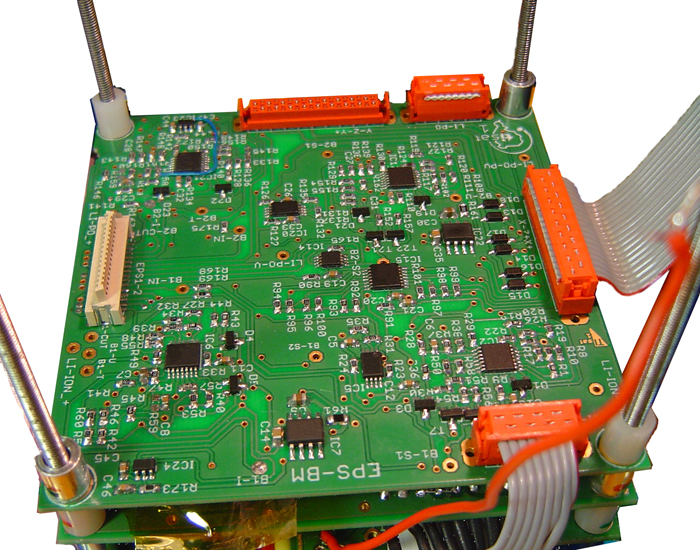

BM and TU

Independent pieces of hardware were designed to manage each of the two batteries.

Several failure scenarios of the electronic circuits were considered and countermeasures were built in. The BM is able to provide power to the spacecraft independently from the On Board Computer (OBC); by working OBC though, firmware monitors the status of the EPS and optimizes operations.

To counter latchup phenomena much care was dedicated in chosing electronic components and in circuit design.

TIsat-1’s EPS uses as much bipolar technology as possible, bipolar being generally considered more resistant to latchup than CMOS.

Some CMOS components are however unavoidable, specially for CPU and communication processors. The latchup issue was therefore eperimentally analyzed and some simple but effective circuit solutions were applied, both at component level and power supply channel level, with continuous current monitoring and shutdown to recover from latchup.

Acknowledgements

Metallux SA, CH-6850 Mendrisio

SunAge SA, CH-6850 Mendrisio

Qioptiq Ltd. – St. Asaph, UK

Nusil Silicone Technologies – Cedex, France

Documents

Power Supply Survey (PDF, Italian)

Power Budget (XLS)